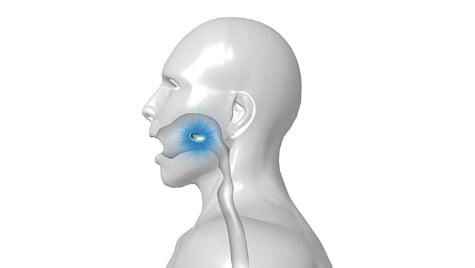

What's OSDrC®

Manufacturing Process and Technical Characteristics of OSDrC® Tablets

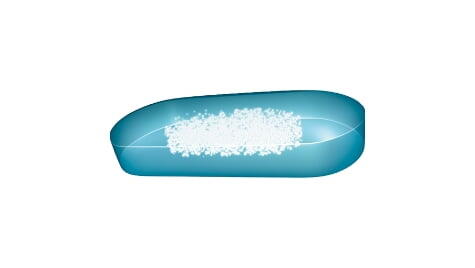

One-Step Manufacture of Cored Tablets with Variable Double-Punch Technology

The OSDrC® rotary tableting machine, with its variable double-punch configuration, supports single-step manufacturing of pharmaceutical products. In addition to the commercial-scale production of conventional cored (tablet-within-a-tablet) tablets, this machine is ideal for manufacturing a variety of high-quality drug products at low cost.

A freely movable tablet punch with a variable double structure

The process of manufacturing core tablets in one step

Various Tablet Configurations Can be Produced Simply by Changing Punches

One-Step Process for Manufacturing Core Tablets

A specialized device that enables innovative tablet manufacturing.

Complex Piston Motion by Cam Function

Additionally, features that prevent cross-contamination of powder between feeders, dust collection on the table surface, removal of residual powder, and recycling of excess powder significantly reduce risk and cost in manufacturing.

also comes equipped with several highly advanced functions conforming to Good Manufacturing Practice (GMP) standards, including a pressure monitor for each layer, automatic sampling, and an automatic exclusion mechanism.